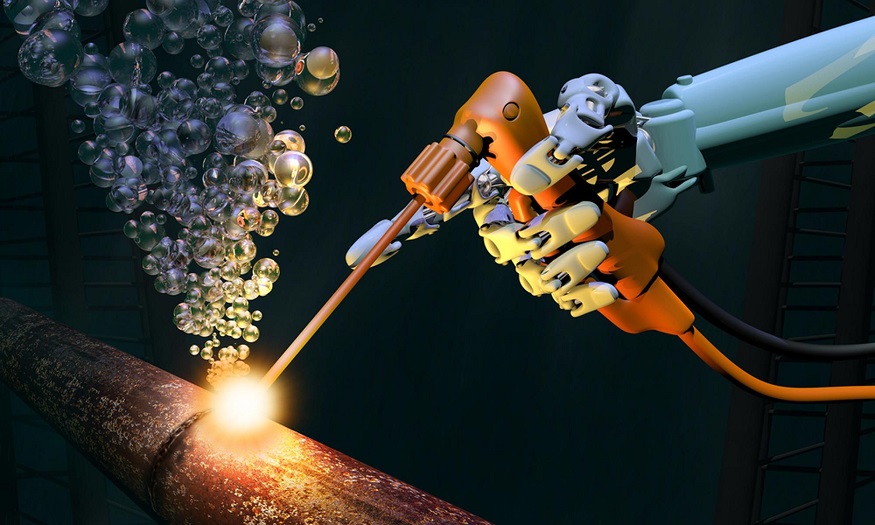

Underwater welding: Risks & Safety Measures

Welding is a risky process and requires a lot of precautionary measures, from safety goggles, head-gear to welding suits. Now imagine the kinds of risks involved in underwater welding and the safety measures required for that! Actually, do not just imagine it. We will walk you through it, with the help of this article.

The first rule in welding is that safety is numero uno and safety standards should be met. With higher risk, the need for best quality safety raises exponentially. The thing about underwater welding is that the risk is that of two jobs, welding as well as diving. The risks, that we will talk about in detail, are more prevalent to wet welding than dry welding, for obvious reasons. But the precautions must be taken by all welder-divers equally. Now let’s look at these hazards one by one.

-

Electric shock:

All welders who perform underwater welding are very well aware of this risk, since they are surrounded by water and their job is dependent on electricity and heat. Things like the welding machines, welding consumable and welding electrode being used may face electrical failure.

To eliminate this risk, the welders can take a bunch of precautions; which will have to be taken care of on the surface, not underwater. One point is to ensure that direct current or DC is being used instead of alternating current or AC. The other thing to keep in mind is of course wearing proper gear for it.

The welding electrodes used here should be waterproof insulated electrodes. The cables should be watertight and insulated as well. All power supplies are to be kept on rubber.

-

Underwater explosions:

Welding underwater produces gases like hydrogen, oxygen and carbon monoxide, which are all highly flammable. All these gases come out in the form of bubbles, ultimately helping the welder.

To keep underwater explosions at bay, one should keep an eye out for areas where gases are getting trapped so that a tube or a pipe can help the gas let out. Welding from a high point to a lower point helps with this as well.

Another important detail to keep in mind is that if the electrodes are at over 10,000 degrees Fahrenheit, they are more susceptible to explode, even with a tiny spark. Letting some water in to cool down is a better option, even though it hampers the quality of the weld.

-

Decompression sickness:

Also commonly called diver bends, decompression sickness is a physical illness that underwater welders are susceptible to. This is more related to the diving part of their job than the welding part of it.

This occurs due to the pressure change in their surroundings. When the welder makes their journey back to the surface quicker, they push dissolved gases into different parts of their body, which travels directly through the bloodstream. The symptoms of diver bends or decompression sickness is fatigue, and pain in ears, lungs, joints, and spinal cord.

To eliminate this risk, a device called, ‘diving bell’ can be used to transport the welder to deeper levels, in and out. The pressure levels will thus change slowly and the body will welcome the change in pressure more willingly.

A few other things the welder-diver should avoid are: consuming alcohol after reaching the surface, not drinking enough water, flying shortly after coming out and over-diving.

-

Freezing:

As odd as it sounds, this is a real threat to welder-divers. The deeper they go, the colder it is. Exposure to even a small amount of water at that level will put one’s health at danger and can lead to hypothermia and respiratory issues, or even death.

To eliminate this hazard , scuba diving gear that is well insulated should be used by welder-divers. All the gear should be checked by them and their team for any wear and tear. Of course, along with the suit, they should be wearing insulated gloves too.

We hope this article has made you more aware of the risks that come with underwater welding and how they can be put to a halt. Keep on exploring welding, but remember to stay safe!